Factory Cheap Hot Brass Precision Turned Components – Turned Parts Service – Dongtai Fortune

Factory Cheap Hot Brass Precision Turned Components – Turned Parts Service – Dongtai Fortune Detail:

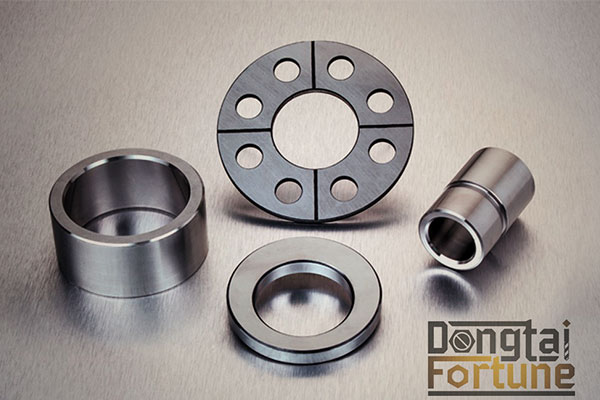

Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool. The workpiece is a piece of pre-shaped material that is secured to the fixture, which itself is attached to the turning machine, and allowed to rotate at high speeds. The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools. The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape.

Turning is used to produce rotational, typically axi-symmetric, parts that have many features, such as holes, grooves, threads, tapers, various diameter steps, and even contoured surfaces. Parts that are fabricated completely through turning often include components that are used in limited quantities, perhaps for prototypes, such as custom designed shafts and fasteners. Turning is also commonly used as a secondary process to add or refine features on parts that were manufactured using a different process. Due to the high tolerances and surface finishes that turning can offer, it is ideal for adding precision rotational features to a part whose basic shape has already been formed.

Turning can be performed on a variety of materials, including most metals and plastics. Common materials that are used in turning include the following:

•Aluminum

•Brass

•Magnesium

•Nickel

•Steel

•Thermoset plastics

•Titanium

•Zinc

Capabilities

|

|

Typical |

Feasible |

|

Shapes: |

Thin-walled: Cylindrical |

|

|

Part size: |

Diameter: 0.02 – 80 in | |

|

Materials: |

Metals |

Ceramics |

|

Surface finish – Ra: |

16 – 125 μin |

2 – 250 μin |

|

Tolerance: |

± 0.001 in. |

± 0.0002 in. |

|

Lead time: |

Days |

Hours |

|

Advantages: |

All materials compatible Very good tolerances Short lead times |

|

|

Applied industry: |

Machine components, engine components, aerospace industry, automotive industry, oil & gas industry, automation components. Maritime industry. | |

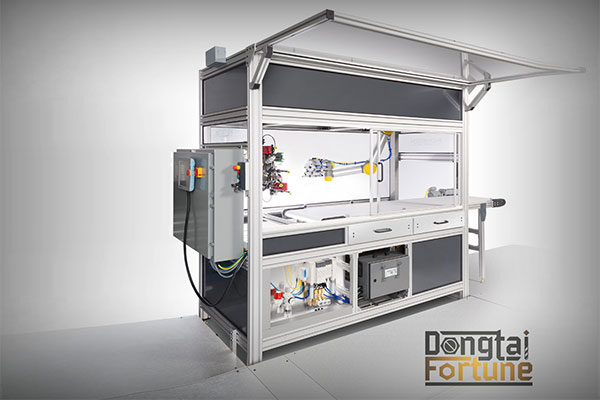

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for Factory Cheap Hot Brass Precision Turned Components – Turned Parts Service – Dongtai Fortune , The product will supply to all over the world, such as: Surabaya, Luxemburg, French, We have been seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.